Study of inorganic based anti-blocks as migration control of slip additive on surface polyethylene monolayer film

Authors

Laily Aulia Agustina , Yeni Dwi Lestari , Arrival Arsyad Adhinanda , Muhammad Naufal Ariesta , Jonghyun Choi , Yuniar Ponco Prananto , Rakhma FebrianiDOI:

10.29303/aca.v7i1.196Published:

2024-04-19Issue:

Vol. 7 No. 1 (2024)Keywords:

inorganic anti-block, coefficient of friction, erucamide, migration, hazeArticles

Downloads

How to Cite

Downloads

Metrics

Abstract

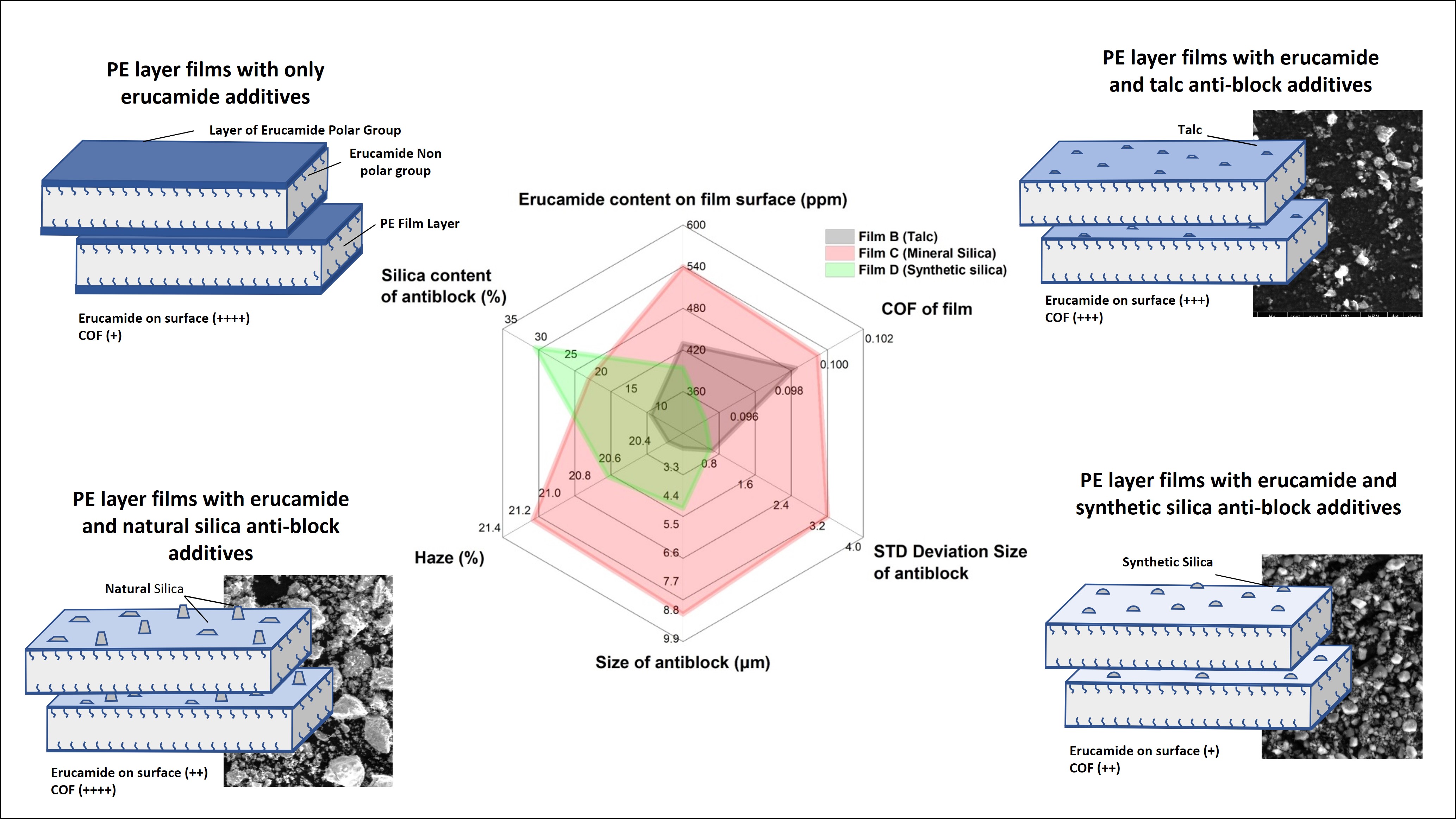

Slip migration must be controlled to maintain the performance and quality of flexible packaging. Inorganic based anti-block materials can be used to control the slip migration. This paper reported the effect of anti-block type on the inhibition of slip migration on polyethylene monolayer film. A series of formulations were made with three different anti-block additives, namely talc, natural silica, and synthetic silica, along with erucamide. The optical properties (haze) and friction properties (COF) were measured to assess the film characteristics as the development of slip migration in the presence of anti-block additives. Characterization of the anti-block material was conducted by SEM-EDX, slip additive type was examined by GC-MS, while the slip content on the surface was analysed by FTIR. The result showed that after seven days, synthetic silica anti-block gives COF up to 0.095, with the trace erucamide content on the film surface of 394 ppm, the lowest amongst other types of the anti-block used. The smaller particle size and higher silica content on synthetic silica anti-block resulted in better friction properties which act as a good barrier to limit a migration of erucamide onto the film surface.

References

Perera, K. Y., Jaiswal, S., & Jaiswal, A. K. (2022). A review on nanomaterials and nanohybrids based bio-nanocomposites for food packaging. Food Chemistry, 376(December 2021), 131912. https://doi.org/10.1016/j.foodchem.2021.131912

Coles, R. (2011). Food and beverage packaging company. In Wiley Blackwell (Richard Co, hal. 49–56). A John Wiley & Son. https://www.dodaco.eu/en/ingredients/

Marturano, V., Cerruti, P., & Ambrogi, V. (2019). Polymer additives. Physical Sciences Reviews, 2(6). https://doi.org/10.1515/psr-2016-0130

Morris, B. A. (2022). The science and technology of flexible packaging: multilayer films from resin and process to end use. William Andrew.

Yang, Z., Peng, H., Wang, W., & Liu, T. (2010). Crystallization behavior of poly(ε-caprolactone)/layered double hydroxide nanocomposites. Journal of Applied Polymer Science, 116(5), 2658–2667. https://doi.org/10.1002/app

Browning, R, Goy Teck Lim, Allan Moyse, Luyi Sun, H.-J. S. (2006). Effects of Slip Agent and Talc Surface-Treatment on the Scratch Behavior of Thermoplastic Olefin. Polymer Engineering & Science, 45(5), 601-608. https://doi.org/10.1002/pen

Radosta, J. A., & Riley, W. D. (1991). Treated talc as an effective anti-block for LDPE blown film. Journal of Plastic Film & Sheeting, 7(3), 247–258. https://doi.org/10.1177/875608799100700306

Dulal, N., Shanks, R., Gengenbach, T., Gill, H., Chalmers, D., Adhikari, B., & Pardo Martinez, I. (2017). Slip-additive migration, surface morphology, and performance on injection moulded high-density polyethylene closures. Journal of Colloid and Interface Science, 505, 537–545. https://doi.org/10.1016/j.jcis.2017.06.040

Intan, P., Ningrum, P., Mulyasuryani, A., & Febriani, R. (2023). Pengaruh Bahan Aditif Polimer Slip terhadap Karakteristik Film Polietilen. 06(01), 75–84.

Catino, J. W., & Gardiner, J. L. (2004). Surface structural characterization of antiblock films containing erucamide. Microscopy and Microanalysis, 10(SUPPL. 2), 626–627. https://doi.org/10.1017/S1431927604884964

Janorkar, A. V., Hirt, D. E., & Wooster, J. J. (2004). Effect of erucamide and silica loadings on COF behavior of POP multilayer films in repetitive testing. Polymer Engineering and Science, 44(1), 34–44. https://doi.org/10.1002/pen.20003

Azad, A. (2017). Application of porous concrete containing adsorbent as a new approach in improving the quality of urban runoff. In Master of Science Thesis. Semnan University.

Grum, J. (2008). Book Review: Plastics Additives Handbook, 5th Edition by H. Zweifel. International Journal of Microstructure and Materials Properties, 3(2/3), 451. https://doi.org/10.1504/ijmmp.2008.018747

Boulos, T. R., Ibrahim, S. S., & Yehia, A. (2016). The Art of Talc Flotation for Different Industrial Applications. Journal of Minerals and Materials Characterization and Engineering, 04(03), 218–227. https://doi.org/10.4236/jmmce.2016.43020

Marzbani, P., Resalati, H., Ghasemian, A., & Shakeri, A. (2016). Surface Modification of Talc Particles with Phthalimide: Study of Composite Structure and Consequences on Physical, Mechanical, and Optical Properties of Deinked Pulp. BioResources, 11(4), 8720–8738. https://doi.org/10.15376/biores.11.4.8720-8738

Charnay, C., Lagerge, S., & Partyka, S. (2001). Assessment of the surface heterogeneity of talc materials. Journal of Colloid and Interface Science, 233(2), 250–258. https://doi.org/10.1006/jcis.2000.7259

Ciullo, P. A., & Anderson, J. (2002). Industrial talc. Journal of Coatings Technology, 74(934), 15–19. https://doi.org/10.1007/bf02697955

Dirè, S., Facchin, G., Ceccato, R., Guarino, L., Sassi, A., & Gleria, M. (2002). Hydroxylated Cyclophosphazene / Silica Hybrid Materials : Synthesis and Characterization. Journal of Inorganic and Organometallic Polymers and Materials, 12(3), 59–78.

Munasir, Dewanto, A. S., Yulianingsih, A., Saadah, I. K. F., Supardi, Z. A. I., Mufid, A., & Taufiq, A. (2017). Composites of Fe3O4/SiO2 from Natural Material Synthesized by Co-Precipitation Method. IOP Conference Series: Materials Science and Engineering, 202(1). https://doi.org/10.1088/1757-

899X/202/1/012057

Munasir, Imam Supardi, Z. A., Mashadi, Nisa, Z., Kusumawati, D. H., Putri, N. P., Taufiq, A., Sunaryono, Hidayat, N., & Darminto. (2018). Phase Transition of SiO2 Nanoparticles Prepared from Natural Sand: The Calcination Temperature Effect. Journal of Physics: Conference Series, 1093(1). https://doi.org/10.1088/1742-6596/1093/1/012025

Li, K. M., Jiang, J. G., Tian, S. C., Chen, X. J., & Yan, F. (2014). Influence of silica types on synthesis and performance of amine-silica hybrid materials used for CO2 capture. Journal of Physical Chemistry C, 118(5), 2454–2462. https://doi.org/10.1021/jp408354r

Garrido-López, Á., Esquiu, V., & Tena, M. T. (2007). Comparison of three gas chromatography methods for the determination of slip agents in polyethylene films. Journal of Chromatography A, 1150(1–2), 178–182. https://doi.org/10.1016/j.chroma.2006.11.090

Rawls, A. S., Hirt, D. E., Havens, M. R., & Roberts, W. P. (2002). Evaluation of surface concentration of erucamide in LLDPE films. Journal of Vinyl and Additive Technology, 8(2), 130–138. https://doi.org/10.1002/vnl.10353

Rahmawati, A. (2015). The Effect of utilizing Polyethylene (PE) and High Density Polyethylen (HDPE) Plastic on Lataston_WC at Marshall Characteristic). Jurnal Ilmiah Semesta Teknika, 18(2), 147–159.

J. P. Greene. (2021). Automotive plastics and composites: materials and processing. In J. P. Greene (Ed.), Materials and Processing (Oxford : W, hal. 1–23). William Andrew.

Awasthi, N. P., Upadhayay, S. K., & Singh, R. P. (2008). Kinetic Investigation of Erucamide Synthesis Using Fatty Acid and Urea. Journal of Oleo Science, 475(9), 471–475.

Sankhe, S. Y., Janorkar, A. V., & Hirt, D. E. (2003). Characterization of Erucamide Profiles in LLDPE Films: Depth-profiling Attempts using FTIR Photoacoustic Spectroscopy and Raman Microspectroscopy. Journal of Plastic Film and Sheeting, 19(1), 16–29. https://doi.org/10.1177/875608703035509

Hameed, A. Z., & Lee, S. J. (2023). Sustainable Drag Reduction of Fatty Acid Amide-Based Oleogel Surface Under High-Speed Shear Flows. Advanced Materials Interfaces, 10(9). https://doi.org/10.1002/admi.202202057

Browning, R. L. (2006). Quantitative characterization of polymer scratch behavior using a standardized scratch test [Texas A&M University]. http://hdl.handle.net/1969.1/5988

Malacari, P. . (2017). Talc as Antiblocking in LLDPE: Performance Screening of Different Talc Grades versus other Mineral Antiblocking. SPE international Polyolefin Conference, 1–8.

Markarian, J. (2007). Slip and antiblock additives: surface medication for film and sheet. Plastics, Additives and Compounding, 9(6), 32–35. https://doi.org/10.1016/S1464-391X(07)70156-3

Davidson DL, S. D. (2004). Unique antiblocks for high clarity polyethylene film. SPE ANTEC conference, 1111–1116.

Patel, P., & Savargaonkar, N. (2007). A review of additives for plastics: Slips and antiblocks. Plastics Engineering, 63(1), 48–51. https://doi.org/10.1002/j.1941-9635.2007.tb00033.x

Coupland, K., and A. M. (1997). Plastic Film & Sheeting. In Wiley Blackwell (Vol. 13, Nomor 4, hal. 142).

Keck-Antoine, K., Lievens, E., Bayer, J., Mara, J., Jung, D. S., & Jung, S. L. (2009). Additives to design and improve the performance of multilayer flexible packaging. Multilayer Flexible Packaging: Technology and Applications for the Food, Personal Care, and Over-the-Counter Pharmaceutical Industries, 37–56. https://doi.org/10.1016/B978-0-8155-2021-4.10004-8

Wypych, G. (2021). Handbook of antiblocking, release, and slip additives. Elsevier.

Author Biographies

Laily Aulia Agustina, LyondellBasell Advanced Polyolefins

Department of Product & Application Development

Yeni Dwi Lestari, LyondellBasell Advanced Polyolefins

Department of Product & Application Development

Arrival Arsyad Adhinanda, LyondellBasell Advanced Polyolefins

Department of Product & Application Development

Muhammad Naufal Ariesta, LyondellBasell Advanced Polyolefins

Department of Product & Application Development

Jonghyun Choi, Basell Polyolefins Korea Ltd

Department of Application Development and Technical Service

Yuniar Ponco Prananto, Brawijaya University

Department of Chemistry

Rakhma Febriani, LyondellBasell Advanced Polyolefins

Department of Product & Application Development

License

Copyright (c) 2024 Laily Aulia Agustina, Yeni Dwi Lestari, Arrival Arsyad Adhinanda, Muhammad Naufal Ariesta, Jonghyun Choi, Yuniar Ponco Prananto, Rakhma Febriani

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Authors who publish with ACA: Acta Chimica Asiana agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License. This license allows authors to use all articles, data sets, graphics, and appendices in data mining applications, search engines, web sites, blogs, and other platforms by providing an appropriate reference. The journal allows the author(s) to hold the copyright without restrictions and will retain publishing rights without restrictions.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in ACA: Acta Chimica Asiana.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).

Indonesian Chemical Society, Chapter Nusa Tenggara. Jalan Majapahit 62 Mataram, University of Mataram, 83125, Indonesia

Indonesian Chemical Society, Chapter Nusa Tenggara. Jalan Majapahit 62 Mataram, University of Mataram, 83125, Indonesia