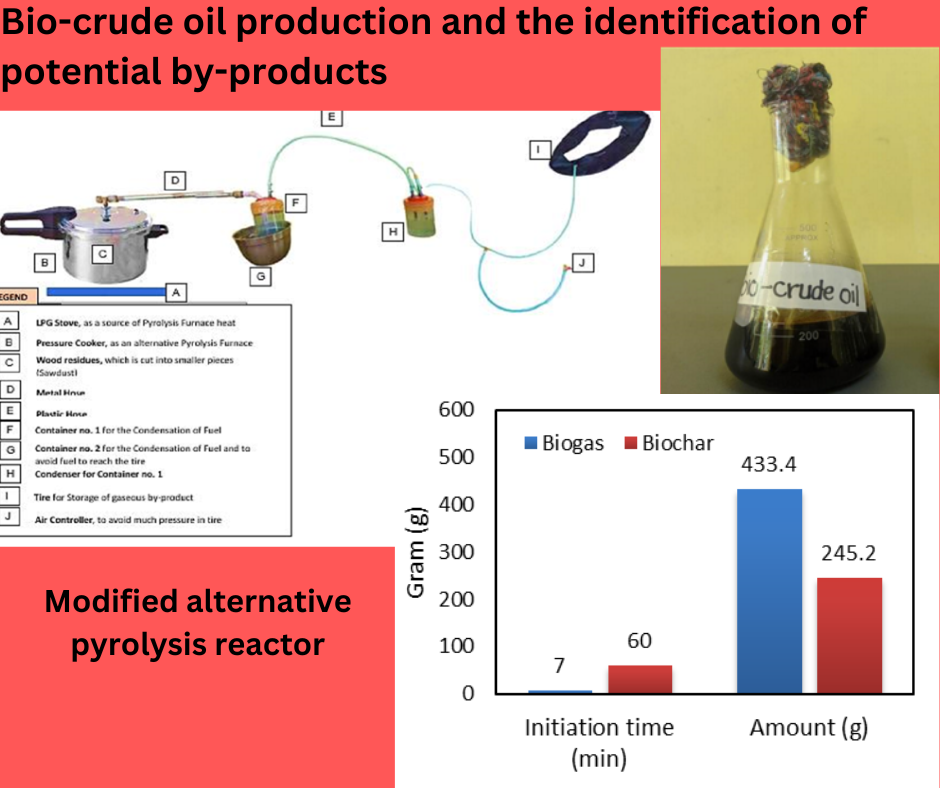

Utilization of Pili (Canarium ovatum) sawdust in bio-crude oil production and the identification of potential by-products through thermochemical conversion

DOI:

10.29303/aca.v7i2.188Published:

2024-10-31Issue:

Vol. 7 No. 2 (2024)Keywords:

Viscosity, Distillate, Thermochemical Conversion, Pyrolysis Method, By-product, Flammability and Combustibility, standardizationArticles

Downloads

How to Cite

Prado, J., Mendez, J. C. ., Brillante, F., & Ocampo, D. (2024). Utilization of Pili (Canarium ovatum) sawdust in bio-crude oil production and the identification of potential by-products through thermochemical conversion. Acta Chimica Asiana, 7(2), 464–470. https://doi.org/10.29303/aca.v7i2.188

Downloads

Download data is not yet available.

Metrics

Metrics Loading ...

Indonesian Chemical Society, Chapter Nusa Tenggara. Jalan Majapahit 62 Mataram, University of Mataram, 83125, Indonesia

Indonesian Chemical Society, Chapter Nusa Tenggara. Jalan Majapahit 62 Mataram, University of Mataram, 83125, Indonesia