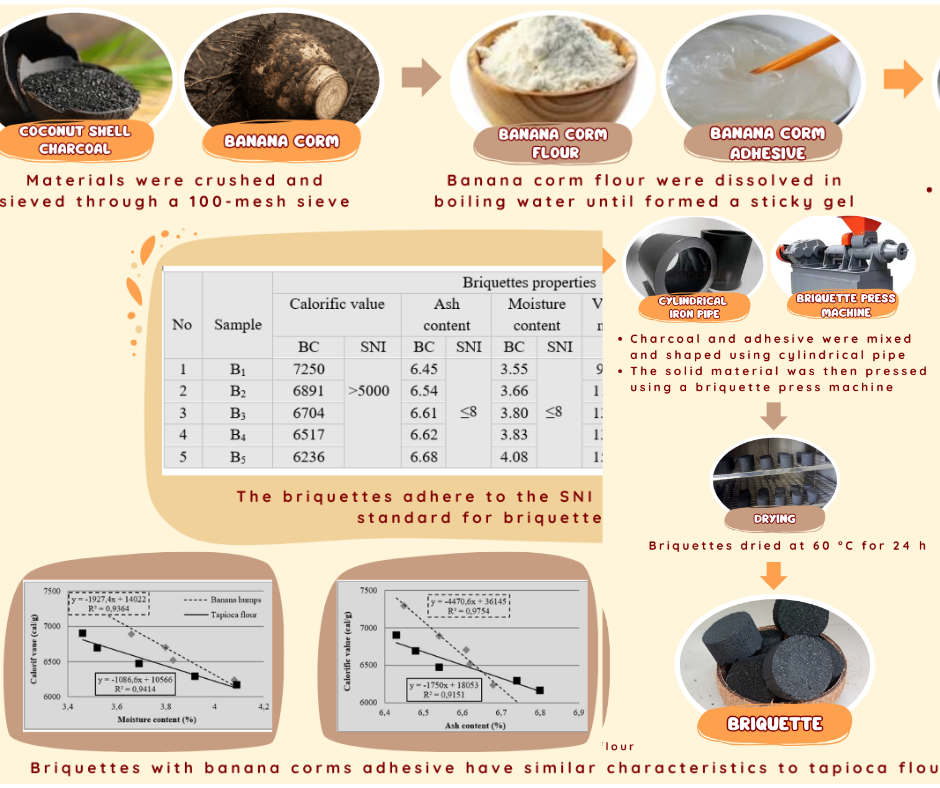

Coconut shell charcoal briquettes production using banana corm adhesive

Authors

Remi Ayu Pratika , Fery Indradewi Armadany , FahyuddinDOI:

10.29303/aca.v8i2.249Published:

2025-11-28Issue:

Vol. 8 No. 2 (2025)Keywords:

Banana corm, adhesive, briquette, coconut charcoalArticles

Downloads

How to Cite

Downloads

Metrics

Abstract

The production of biomass-based briquettes from coconut shell charcoal and banana corm adhesive has been successfully carried out. This research aims to determine whether the banana corm may serve as an adhesive for briquette production from coconut shell charcoal. The concentration of banana corm utilized as adhesive is 10, 20, 30, 40, and 50%. For comparison analysis, this study also employed tapioca flour adhesive with the same concentration. The briquettes adhere to the SNI 01-6235-2000 standard for briquettes. The quality of briquettes is determined based on fixed carbon content and calorific value. The minimum standard calorific value and fixed carbon content are 5000 cal/g and 65%, respectively. Briquettes with a 90:10 ratio (coconut shell charcoal to banana corm adhesive ratio) had the highest calorific value of 7250 cal/g and fixed carbon content of 80.04%. In comparison, the tapioca flour adhesive provides a calorific value and fixed carbon content of 6995 cal/g and 81.09%, respectively. Furthermore, another indicator that determines briquette quality is the content of moisture, ash, and volatile matter. Briquettes with a 90:10 ratio possessed low moisture content (3.55%), ash content (6.45%), volatile matter content (9.96%), and burning rate (0.020 g/sec). This result indicates that the briquettes with a 90:10 ratio exhibit the greatest quality. Briquettes with banana corms adhesive have similar characteristics to tapioca flour, especially in terms of calorific value. As a result, the highlight of this research lies in offering banana corm, which has scientific contribution and future potential as an alternative adhesive in the briquetting process

References

Ahmad, T. & Danish, M. (2017). Prospects of banana waste utilization in wastewater treatment: A review. Journal of Environmental Management 206, 330–348. https://doi.org/10.1016/j.jenvman.2017.10.061

Ajimotokan, H.A., Ehindero, A.O., Ajao, K.S., Adeleke, A.A., Ikubanni, P.P. & Shuaib-Babata, Y.L. (2019). Combustion characteristics of fuel briquettes made from charcoal particles and sawdust agglomerates. Scientific African 6, e00202. https://doi.org/10.1016/j.sciaf.2019.e00202

Akam, N.G., Diboma, B.S., Mfomo, J.Z., Ndiwe, B., Bôt, B.V. V Biwolé, A. B. (2024). Physicochemical characterization of briquette fuel produced from cocoa pod husk case of Cameroon. Energy Reports 11, 1580–1589.

https://doi.org/10.1016/j.egyr.2024.01.029

Anis, S., Fitriyana, D.F., Bahatmaka, A., Anwar, M.C., Ramadhan, A.Z., Anam, F.C., Permana, R.A., Hakim, A.J., Da Silva Guterres, N.F. & De Sousa Da Silva, M. (2023). Effect of adhesive type on the quality of coconut shell charcoal briquettes prepared by the screw extruder machine. Journal of Renewable Materials 12(2), 381-396. https://doi.org/10.32604/jrm.2023.047128

Duangkham, S. & Thuadaij, P. (2023). Characterization of charcoal briquettes produced from blending rice straw and banana peel. Heliyon 9(6), e16305. https://doi.org/10.1016/j.heliyon.2023.e16305

Ibitoye, S.E., Mahamood, R.M., Jen, T.-C., Loha, C. & Akinlabi, E.T. (2023). An overview of biomass solid fuels: Biomass sources, processing methods, and morphological and microstructural properties. Journal of Bioresources and Bioproducts 8(4), 333–360.

https://doi.org/10.1016/j.jobab.2023.09.005

Karuppuchamy, A.K.R. & Ra, S. (2024). Novel banana core stem fiber from agricultural biomass for lightweight textile applications. Industrial Crops and Products, 209, 117985. https://doi.org/10.1016/j.indcrop.2023.117985

Kipngetich, P., Kiplimo, R., Tanui, J.K. & Chisale, P. (2023). Effects of carbonization on the combustion of rice husks briquettes in a fixed bed. Cleaner Engineering and Technology 13, 100608.

https://doi.org/10.1016/j.clet.2023.100608

Kipngetich, P., Kiplimo, R., Tanui, J.K. & Chisale, P.C. (2022). Optimization of combustion parameters of carbonized rice husk briquettes in a fixed bed using RSM technique. Renewable Energy 198, 61–74. https://doi.org/10.1016/j.renene.2022.07.130

Kpalo, S.Y., Zainuddin, M.F., Manaf, L.A. & Roslan, A.M. (2020). A review of technical and economic aspects of biomass briquetting. Sustainability 12(11), 4609. https://doi.org/10.3390/su12114609

Kumar, J.A., Kumar, K.V., Petchimuthu, M., Iyahraja, S. & Kumar, D.V. (2020). Comparative analysis of briquettes obtained from biomass and charcoal. Materials Today Proceedings 45, 857–861.

https://doi.org/10.1016/j.matpr.2020.02.918

Lu, Y.-C., Brabie, L., Karasev, A.V. & Wang, C. (2022). Applications of hydrochar and Charcoal in the iron and Steelmaking Industry—Part 2: Carburization of liquid iron by addition of Iron–Carbon briquettes. Sustainability 14(9), 5383.

https://doi.org/10.3390/su14095383

Palanisami, E., Velusamy, S., Al-Zaqri, N. & Boshaala, A. (2023). Characterization and energy evaluation analysis of agro biomass briquettes produced from Gloriosa superba wastes and turmeric leave wastes using cassava flour as binder. Biomass Conversion and Biorefinery 13(12), 11321–11337. https://doi.org/10.1007/s13399-023-04543-9

Zhang, P. & Hamaker, B.R. (2011) Banana flour structure and digestibility. Carbohydrate Polymers 87(2), 1552–1558.

https://doi.org/10.1016/j.carbpol.2011.09.053

Nikiema, J., Asamoah, B., Egblewogbe, M.N.Y.H., Akomea-Agyin, J., Cofie, O.O., Hughes, A.F., Gebreyesus, G., Asiedu, K.Z. & Njenga, M. (2022). Impact of material composition and food waste decomposition on characteristics of fuel briquettes. Resources Conservation & Recycling Advances 15, 200095.

https://doi.org/10.1016/j.rcradv.2022.200095

Zhang, G. Sun, Y. & Xu, Y. (2017) Review of briquette binders and briquetting mechanism. Renewable and Sustainable Energy Reviews 82, 477–487.

https://doi.org/10.1016/j.rser.2017.09.072

Nonsawang, S., Juntahum, S., Sanccormu, P., Suaili, W., Senawong, K. & Laloon, K. (2024). Unlocking renewable fuel: Charcoal briquettes production from agro-industrial waste with cassava industrial binders. Energy Reports 12, 4966–4982.

https://doi.org/10.1016/j.egyr.2024.10.053

Pari, G., Efiyanti, L., Darmawan, S., Saputra, N.A., Hendra, D., Adam, J., Inkriwang, A. & Effendi, R. (2023). Initial Ignition Time and Calorific Value Enhancement of Briquette with Added Pine Resin. Journal of the Korean Wood Science and Technology 51(3), 207–221.

https://doi.org/10.5658/WOOD.2023.51.3.207

Mao, S., Zeng, G., Xing, J., Dong, Y., Aladejana, J.T., Chu, F., Wang, C. & Li, J. (2024). High water retention bio-mass adhesives inspired by hydrogels for engineering applications. Industrial Crops and Products 224, 120283.

https://doi.org/10.1016/j.indcrop.2024.120283

Puspita, P.S., Hermana, W. & Nahrowi, N. (2019). Effect of isoamylase application on chemical characteristic of cassava root meal flour. IOP Conference Series Earth and Environmental Science 251, 012058. https://doi.org/10.1088/1755-1315/251/1/012058

Putri, T.R., Adhitasari, A., Paramita, V., Yulianto, M.E. & Ariyanto, H. D. (2023). Effect of different flour on the characteristics of edible film as functional packaging in fresh meat or meat products: A review. Materials Today Proceedings 87, 192–199.

https://doi.org/10.1016/j.matpr.2023.02.396

Rabier, F., Temmerman, M., Bohm, T., Hartmann, H., Daugbjergjensen, P., Rathbauer, J., Carrasco, J. & Fernandez, M. (2006). Particle density determination of pellets and briquettes. Biomass and Bioenergy 30(11), 954–963.

https://doi.org/10.1016/j.biombioe.2006.06.006

Saeed, A.A.H., Harun, N.Y., Bilad, M.R., Afzal, M.T., Parvez, A.M., Roslan, F.A.S., Rahim, S.A., Vinayagam, V.D. & Afolabi, H.K. (2021). Moisture Content Impact on Properties of Briquette Produced from Rice Husk Waste. Sustainability 13(6), 3069. https://doi.org/10.3390/su13063069

Suryaningsih, S., Nurhilal, O., Widyarini, R.A., Suhendi, N. & Rukiah, N. (2019). The analysis of ignition and combustion properties of the burning briquettes made from mixed biomass of rice husk and corn cob. IOP Conference Series Materials Science and Engineering 550(1), 012006. https://doi.org/10.1088/1757-899X/550/1/012006

Zięzio, M., Charmas, B., Jedynak, K., Hawryluk, M. & Kucio, K. (2020). Preparation and characterization of activated carbons obtained from the waste materials impregnated with phosphoric acid(V). Applied Nanoscience 10(12), 4703–4716. https://doi.org/10.1007/s13204-020-01419-6

Suryaningsih, S., Resitasari, R. & Nurhilal, O. (2019). Analysis of biomass briquettes based on carbonized rice husk and jatropha seed waste by using newspaper waste pulp as an adhesive material. Journal of Physics Conference Series 1280(2), 022072.

https://doi.org/10.1088/1742-6596/1280/2/022072

Mathew, S.P., Nadir, Y. & Arif, M.M. (2019). Experimental study of thermal properties of concrete with partial replacement of coarse aggregate by coconut shell. Materials Today Proceedings 27, 415–420. https://doi.org/10.1016/j.matpr.2019.11.249

Yirijor, J. & Bere, A.A.T. (2024). Production and characterization of coconut shell charcoal-based bio-briquettes as an alternative energy source for rural communities. Heliyon 10(16), e35717.

License

Copyright (c) 2025 Remi Ayu Pratika, Fery Indradewi Armadany, Fahyuddin

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Authors who publish with ACA: Acta Chimica Asiana agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License. This license allows authors to use all articles, data sets, graphics, and appendices in data mining applications, search engines, web sites, blogs, and other platforms by providing an appropriate reference. The journal allows the author(s) to hold the copyright without restrictions and will retain publishing rights without restrictions.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in ACA: Acta Chimica Asiana.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).

Indonesian Chemical Society, Chapter Nusa Tenggara. Jalan Majapahit 62 Mataram, University of Mataram, 83125, Indonesia

Indonesian Chemical Society, Chapter Nusa Tenggara. Jalan Majapahit 62 Mataram, University of Mataram, 83125, Indonesia