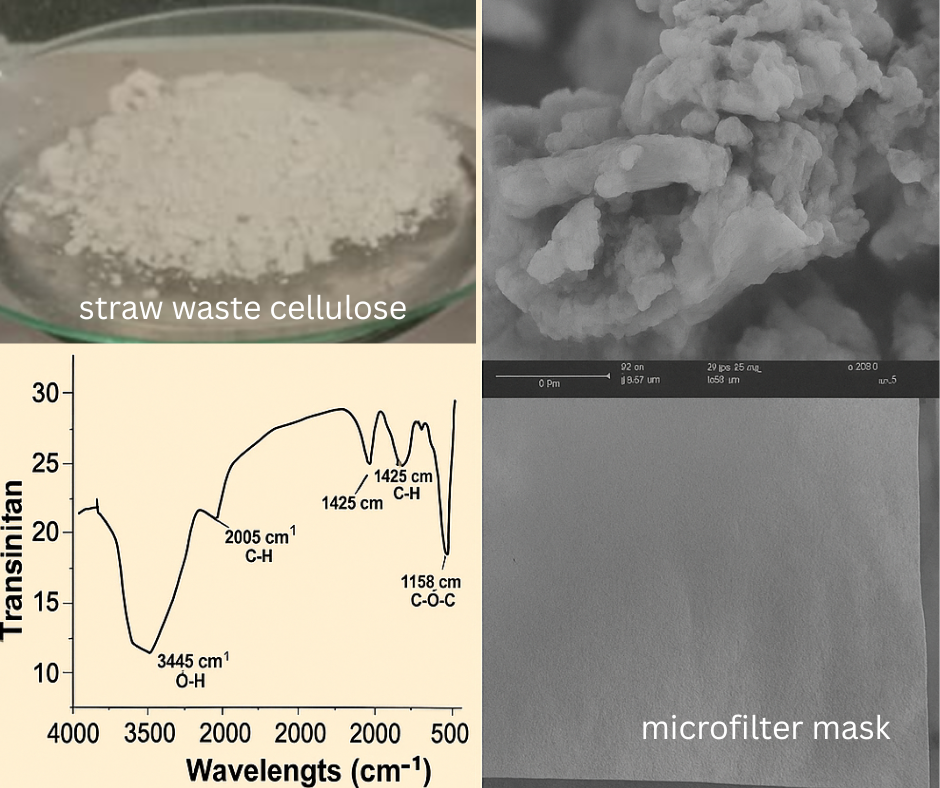

Effectiveness test of microfilter mask based on straw waste cellulose fiber biopolymer

Authors

Hazi Rofiqoh , Baiq Hizanatul Ummah , Imam Galih Hanafi , Baiq Nely Budhiartini , Murniati Murniati , Chang-Nan ChenDOI:

10.29303/aca.v8i1.172Published:

2025-05-31Issue:

Vol. 8 No. 1 (2025)Keywords:

cellulosa, straw waste, microfilter maskArticles

Downloads

How to Cite

Downloads

Metrics

Abstract

Straw waste, which is often underutilized, contains abundant cellulose that holds potential as a raw material for environmentally friendly filtration technologies. The conversion of agricultural waste into value-added products, such as mask microfilters, aligns with the increasing demand for sustainable materials, particularly in the context of public health protection. Harnessing cellulose from straw offers a promising alternative to synthetic fibers commonly used in mask production, while simultaneously addressing waste management challenges. This study aims to determine the characterization of microfilter masks from straw waste and the effectiveness of straw microfilters used in cloth masks. Cellulose from straw waste can be used as a mask microfilter by going through several stages, such as: preparation, extraction, delignification, bleaching, characterization, and making mask microfilters and effectiveness tests. The characterization of structure, morphology and topology from the straw waste cellulose has not been fully degraded from lignin as shown from the aromatic C = C stretching vibrations on lignin at wave numbers 1638.34 cm-1, 1648 cm-1, and 1583.56 cm-1 of FTIR also SEM tools at 3600 times magnification. The effectiveness of the microfilter mask is 94% and 91% as evidenced by each bacterial filtration test and the decreasing data of the dust filtration test.

References

Owens, L. P., & Hubbe, M. A. (2023). Performance Factors for Filtration of Air Using Cellulosic Fiber-based Media: A Review. BioResources, 18(1), 2440–2519.

Siregar, S. H., Rahmadini, S., Hasmalina, N., Rizki, R. A., & Eri, K. (2023). Pulp synthesis using bamboo raw materials through unbleached and bleached processes. Acta Chimica Asiana, 6(1), 247-253.

Chen, M., Ma, Y., Xu, Y., Chen, X., Zhang, X., & Lu, C. (2013). Isolation and characterization of cellulose fibers from rice straw and its application in modified polypropylene composites. Polymer-Plastics Technology and Engineering, 52(15), 1566-1573..

Sun, X. F., Sun, R. C., Fowler, P., & Baird, M. S. (2003). Isolation and characterization of cellulose obtained by a two-stage treatment with organosolv and cyanamide activated hydrogen peroxide from straw. Carbohydrate Polymers, 52(4), 437–443.

Lu, H., Wang, X., & Zhang, L. (2018). Cellulose, nanocellulose, and antimicrobial materials for the development of biodegradable and reusable face masks. Bioresources.

Rainey, T. J., et al. (2020). Developing of Mask Material Using Nanocellulose to Fight against COVID-19. Sugar Asia Magazine.

Wang, J., Liu, S., Yan, X., Jiang, Z., Zhou, Z., Liu, J., ... & Jiang, W. (2021). Biodegradable and reusable cellulose-based nanofiber membrane preparation for mask filter by electrospinning. Membranes, 12(1), 23..

Nasri‐Nasrabadi, B., Behzad, T., & Bagheri, R. (2014). Extraction and characterization of rice straw cellulose nanofibers by an optimized chemomechanical method. Journal of Applied Polymer Science, 131(7).

Jadaun, S., Upadhyay, N., & Siddiqui, S. (2025). Isolation and characterization of cellulose nanofibers from rice straw using ultrasonication-assisted extraction technique coupled with high shear dispersion. Biomass Conversion and Biorefinery, 1-17.

Lu, P., & Hsieh, Y. L. (2012). Preparation and characterization of cellulose nanocrystals from rice straw. Carbohydrate Polymers, 87(1), 564-573.

Sun, X., Wu, Q., & Ren, S. (2021). Recent advances in biomass-derived materials for personal protective equipment. Materials Today Sustainability, 12, 100059.

Putri, R. D., & Khairurrijal. (2020). Utilization of pineapple fiber as natural-based nanofiber mask filter material. IOP Conf. Ser.: Mater. Sci. Eng., 852, 012089.

Badan Pusat Statistik Nusa Tenggara Barat. (2021). Statistik Pertanian Provinsi Nusa Tenggara Barat 2021.

Owens, L. P., & Hubbe, M. A. (2023). Performance Factors for Filtration of Air Using Cellulosic Fiber-based Media: A Review. BioResources, 18(1), 2440–2519.

Liu, L., et al. (2022). Development of silica–cellulose composite membranes for advanced filtration applications. Carbohydrate Polymers, 287, 119353.

Zhao, M., Liao, L., Xiao, W., Yu, X., Wang, H., Wang, Q., ... & Cui, Y. (2020). Household materials selection for homemade cloth face coverings and their filtration efficiency enhancement with triboelectric charging. Nano Letters, 20(7), 5544–5552.

Lu, P. & Hsieh, Y. L. (2012). Preparation and Characterization of Cellulose Nanocrystals from Rice Straw. Carbohydr Polym, 87 (1), 564-573.

Kumar, A., Y. S. Negi, V.Choudhary & N. K.Bhardwaj. (2014). Characterization of Cellulose Nanocrystals Produced by Acid-Hydrolysis from Sugarcane Bagasse as Agro-Waste. Journal of Materials Physics and Chemistry, 2 (1): 1-8.

Fatriasari, W., W.Syafii, N. Wistara, K. Syamsul & B. Prasetya. (2016). Lignin And Cellulose Changes of Betung Bamboo (Dendrocalamus Asper) Pretreated Microwave Heating. International Journal on Advanced Science Engineering Information Technology, 6 (2), 186-195

Nomanbhay, S.M., R. Hussain & K.Palanisamy. (2013). Microwave-Assisted Alkaline Pretreatment and Microwave Assisted Enzymatic Saccharification of Oil Palm Empty Fruit Bunch Fiber for Enhanced Fermentable Sugar Yield. Journal of Sustainable Bioenergy Systems, 3 (1), 7-17.

Supraba, W., Juliantoni, Y., & Ananto, A. D. (2021). The effect of stirring speeds to the entrapment efficiency in a nanoparticles formulation of java plum’ s seed ethanol extract (syzygium cumini). Acta Chimica Asiana, 4(1), 197-103.

Jonoobi, M., Harun, J., Mathew, A.P., Hussein, M.Z., & Oksman, K. (2010). Preparation of Cellulose Nanofibers with Hydrophobic Surface Characteristic, Cellulose, 17 (1), 299-307.

Lin, N. & Dufresne, A. (2014). Nanocellulose in Biomedicine: Current Status and Future Prospect. European Polymer Journal, 59 (2014), 302-325.

Harper, B. J., Clendaniel, A., Sinche, F., Way, D., Hughes, M., Schardt, J., Simonsen, J., Stefaniak A. B., & Harper, S. L. (2016). Impacts of Chemical Modification on the Toxicity of Diverse Nanocellulose Materials to Depeloving Zebrafish. Cellulose, 23 (3), 1763-1775

License

Copyright (c) 2025 Hazi Rofiqoh, Baiq Hizanatul Ummah, Imam Galih Hanafi, Baiq Nely Budhiartini, Murniati Murniati, Chang-Nan Chen

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Authors who publish with ACA: Acta Chimica Asiana agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License. This license allows authors to use all articles, data sets, graphics, and appendices in data mining applications, search engines, web sites, blogs, and other platforms by providing an appropriate reference. The journal allows the author(s) to hold the copyright without restrictions and will retain publishing rights without restrictions.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in ACA: Acta Chimica Asiana.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).

Indonesian Chemical Society, Chapter Nusa Tenggara. Jalan Majapahit 62 Mataram, University of Mataram, 83125, Indonesia

Indonesian Chemical Society, Chapter Nusa Tenggara. Jalan Majapahit 62 Mataram, University of Mataram, 83125, Indonesia